|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pearl-4426 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Decals Glass Fusing Glass Slumping |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

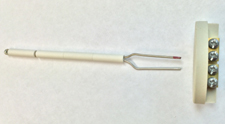

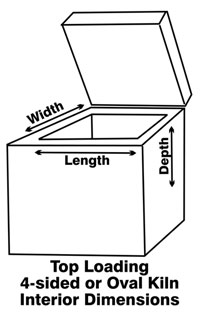

Paragon Pearl-4426 Glass Fusing Kiln The sleek Pearl-4426 Professional Series glass kiln is exciting to look at and to operate. It will help to unlock your potential as a glass artist. The kiln is an investment that pays for itself by firing large glass panels or production loads of small pieces. Imagine how many dichroic pendants you could fire in one load! The Pearl-4426 is proudly made in America by skilled workers, some with decades of experience. This deluxe kiln is designed for those whose livelihood depends on reliable glass production. Assemble glass inside the firing chamberThe Pearl-4426 top lifts away to give convenient access to the shelf area. Heavy-duty air pistons lighten the top. The lid handle is 50” long for convenient opening. Assemble glass pieces directly on the 42” x 24” CoreLite shelf that you have already positioned inside the kiln. A woven rope seal mounted on all four sides of the lid acts as a gasket and cushions the top. The mating surfaces between the lid and sidewalls are hardened and sealed with a special refractory coating. Quartz element tubesThe lid elements are protected in six quartz tubes for a cleaner kiln interior. There is less dust in the kiln, because there are no element grooves; the firebrick top is one continuous, smooth surface. The quartz tubes protect the elements from contamination with foreign materials that could shorten the element life. The quartz tubes absorb very little heat, allowing the elements to heat the firing chamber efficiently. Quartz tubes protect the user from contact with the elements. Elements in the top and sidesFor even heat distribution, the Pearl-4426 includes two rows of sidewall elements, which are mounted in the top section that lifts up with the lid when the kiln is opened. The sidewall element coils are protected in dropped, recessed grooves. Power ratio technologyThe kiln uses advanced power ratio technology, pioneered by Paragon, to balance the heat between the top and side elements. Program the digital controller to balance the heat between the top and sides in increments of 10%. (i.e., 100% top heat - 0% side heat, 50% top - 50% sides, 80% top – 20% sides, etc.) Set the heat balance for any combination desired between the top and sides so that the total heat output equals 100%. Imagine the precise control you will have in adjusting the kiln to slump glass or to improve heat distribution over large fused panels. The two pilot lights on the control panel indicate which elements are firing. The top pilot light glows for the lid elements; the bottom pilot light glows for the sidewall elements. Long-lasting mercury relaysThe Pearl-4426 includes features not found on most competitive kilns. For instance, mercury relays are standard on this kiln. Relays send power to the elements on command from the digital controller. Industrial-grade mercury relays found in the Pearl-4426 far outlast mechanical relays. The life of the quiet, reliable mercury relay has been measured in millions of on/off cycles. Heavy duty kilnThe Pearl-4426 has 3” thick firebrick sidewalls, bottom and top. (This is 1/2” thicker than the firebricks in some competitive kilns on the market.) For long life, the kiln has a 1/2” ceramic fiber expansion joint in the center of the firebrick top and bottom. The heavy tubular frame gives the firing chamber rock-steady support. To keep the electrical components cool, they are mounted inside a ventilated switch box with a double heat shield and air gap between the kiln and box. Costly heavy-gauge nickel-plated copper wiring is covered with high temperature glass-braided insulation. Easy maintenanceThe beautiful Pearl-4426 is designed for easy maintenance. You can quickly remove the top and front sections of the control panel for easy access to the electrical components. The electrical parts are thoughtfully laid out for quick maintenance inside the large control panel. The ventilation slots keep the control panel cool. The control panel includes an on/off switch and two pilot lights. Special limit thermocouple for greater accuracyThe thermocouple, which is the rod that extends into the firing chamber, senses the temperature, so it is critically important to your firings. The Pearl-4426 comes with a ¼” wide Type-K made with special limit wire for accuracy. The tip of the thermocouple is exposed, which results in rapid temperature response time. The new and improved thermocouple replaces our earlier sheathed thermocouple. The new thermocouple is made in America to our exacting standards. Digital temperature controlYou will be amazed at the convenience of digital firing. The reliable solid-state Sentry controller continually monitors the firing so you can spend your time productively without closely watching the kiln. (Please remember, however, to check the kiln during firing and to monitor it near the expected shutoff time.) The sealed touch pad keeps out dust and is easy to wipe clean. Paragon’s innovative controller will help you achieve consistent results from one firing to the next. The controller has powerful features that you will enjoy using. Do you ever wonder how much electricity your kiln uses? The digital controller can figure this for you with the press of a button. Find out how little a kiln actually costs to fire. Environmentally Friendly PaintThe Pearl-4426 has a durable high temperature, water-base finish. We chose water-base paint because of the low emissions during spraying. This creates a safer working environment for our employees and cuts down on pollution. Features of the Pearl-4426

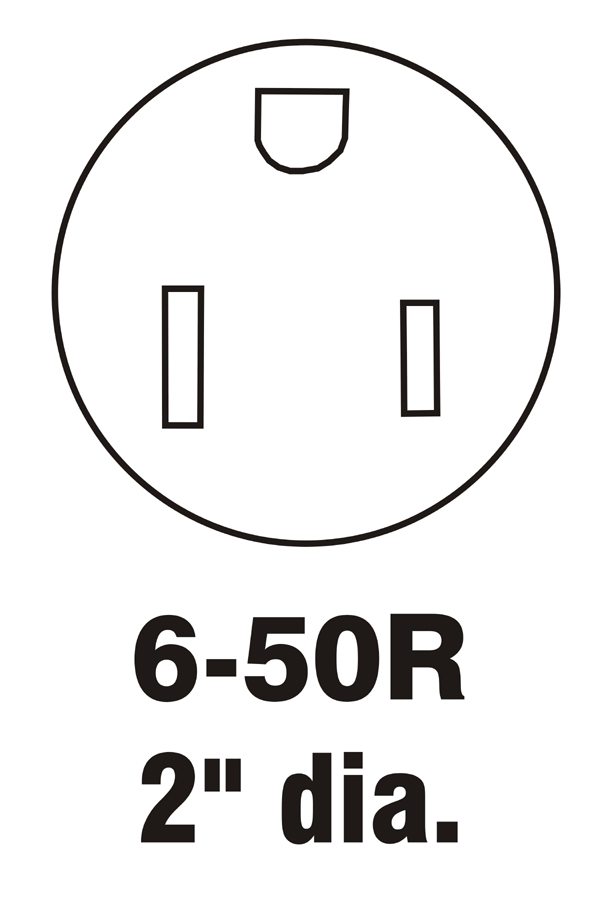

Printed instruction manualsIncluded with your kiln is a 28-page controller instruction manual, a 48-page glass manual, technical bulletins, and blank firing record sheets. The manuals have been painstakingly researched and are written in plain English, printed in two colors, and are fully illustrated. No extra charge for cratingThe Pearl-4426 is shipped in a wooden crate. Inquire about the crating cost of a competitive kiln when figuring prices. Because Paragon is in the central U.S. along a major shipping route, our shipping cost is often lower than that of our competition. We pass this savings on to you. 240 or 208 voltsMost of Paragon’s standard 240 volt kilns can be ordered in 208 volts. To compensate for the lower voltage, Paragon’s 208 volt kilns use a different set of elements so they will perform as well as the equivalent 240 volt models. For this reason, the elements in 240 and 208 volt kilns, even for the same kiln model, are not interchangeable. So please be sure to specify the correct voltage when you order your kiln. By using different elements for different voltages, total watts consumed by different kiln versions remain the same. 240 and 208 kilns of the same model have the same maximum temperature rating.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Sentry 2.0 12-Key Ramp-Hold Manual, 2010 Edition Glass Kiln Instruction & Service Manual |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pearl-4426 Kiln Model/SKU: S1524-1 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||