|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PKM9D, Discontinued |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Knife Making |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

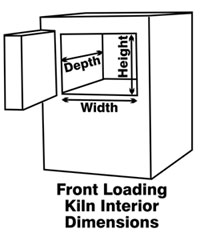

Paragon PKM-9D Heat Treating Furnace Reasons to do Your Own Heat TreatingMachine shops save time with a furnace at their disposal in their own shop. You will no longer send a die out for heat treating, wait for its return and then send it out again for additional heat treating. With a Paragon furnace in your shop, all questions about heat treating formulas are settled. Heat treating is no longer only theory; it is no longer a mysterious, difficult step in making knives. You will master the heat treating process, and you will find out for yourself what heat treating formula works best for your knife designs. Testing and heat treating are at the heart of the knife making adventure. Here is where your confidence as a knife maker deepens. Experiment with differential hardening, an ancient bladesmith technique. Try out the newest tool steels. Are they really as good as the tried and true 52100, D2 and A2? The PKM-9D, our smallest standard-order furnace, measures 8 1/2” wide, 4 1/2” high and 9” deep inside. The PKM-9D is small, but powerful. It will reach 1850° F. within 45 minutes. The PKM-9D fires on a 120 volt, 20 amp circuit. Choose a Side-Swing Door or a Drop DoorYou can now order a PKM-9D knifemaking furnace with either a drop door or a side-swing door. (The photo above shows the traditional drop door.) The drop door is hinged at the bottom; the side-swing door is hinged at the side. The price of the furnace is the same with either door style. Both doors also include the door safety switch. The drop door opens downward with one-handed operation. A counter-weight handle holds the door securely closed. A chain holds the drop door open. The door, whether drop or side-swing, is mounted on a heavy-duty hinge shaft for smooth opening. Because of the rigid case and heavy hinge, the door is sturdy enough for years of faithful service. The door micro safety switch shuts off the power to the elements when the door is opened, yet the temperature controller remains powered. The safety switch is standard on the Paragon PKM-9D. Choose Blue or Black PaintThe standard PKM-9D knifemaking furnaces are painted a rich blue. Or choose the optional black paint. (See the options below the furnace specifications.) Solid ConstructionThe door has a vent hole, so you can see inside the furnace during firing. Metal covers seal the vent holes when not in use. (Always wear green #3 firing safety glasses when looking into a hot furnace.) The furnace is insulated with refractory firebrick. The elements are mounted in dropped, recessed grooves machined into the firebrick. Paragon invented this type of groove in 1952. This groove protects the element for long life and low maintenance. Elements are simple to replace because they’re exposed rather than embedded. You can thread new elements into place following clear instructions in the manual. The temperature sensor (thermocouple) is sheathed for long life. The thermocouple wire is kept inside the control box for protection from the harsh environment of the typical bladesmith shop. The firing chamber is protected by a steel case painted in high temperature blue. A built-in stand lifts the firing chamber safely off your work table, so no extra stand is needed. We use high temperature wire in the switch box for long life. A heat shield, mounted between the switch box and furnace, helps keep the switch box components cool even during extended operation. To further dissipate heat, the switch box is extra large and generously louvered. Each furnace comes with a cord and plug for immediate installation and a one year warranty. Complete InstructionsYour furnace includes a wiring diagram, programming instructions, and heat treating manual. The manual gives you basic heat treating instructions for D2, 440C, ATS 34 and 154 CM. The manual is written in plain English for the beginner. Made in America45% of Paragon’s factory work force has been here over 10 years; 20% have worked here over 20 years. All paragon furnaces are made in America. We are proud to support the American worker. Optional Gas Injection Flow MeterDuring heat treating, scale forms on the surface of the steel. One way to eliminate most scaling is to wrap the steel in stainless steel foil. Another way is to install the gas injection flow meter on your furnace. It is available as either an add-on kit, or you can order the furnace with the meter installed. The meter regulates the flow of an inert gas, such as argon, inside the furnace. The gas displaces the oxygen to prevent most scaling. Please remember that results with the flow meter vary depending on the type of inert gas you use and your level of experience. For more details, click on the link in the Options section below. The knifemaking KitIn addition to the furnace, you will need a Knifemaking Kit, which separates the blades and holds them parallel inside the furnace. Please click the link below in the Options section.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Videos

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Heat Treating Manual for KM & HT Series Sentry 2.0 12-Key Ramp-Hold Manual, 2010 Edition |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PKM9D, Discontinued Kiln Model/SKU: PKM9D |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||