|

|

|

Kiln Pointers

|

|

|

How to Master a Digital Controller |

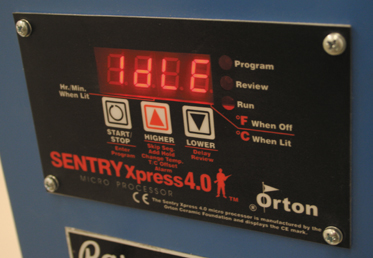

CONTENTS How to Master a Digital Controller Recent Q&As: How to candle a manual fire ceramic kiln; the temperature hold count down timer A Teacher’s Story: The Power of Creativity Memorable Quote ----------- HOW TO MASTER A DIGITAL CONTROLLER Sit down in front of your kiln with the controller instruction manual and become familiar with the basic controller features. Take your time. Enjoy discovering what the controller is capable of doing. Take notes. Mark important sections of the manual. A temperature controller can still seem daunting after reading the manual. So, find several firing schedules. If the manual for your kiln does not include them, find a dozen sample schedules on line, or make up your own. Then practice entering the schedules. (After entering a schedule, press the Stop key to prevent the kiln from firing.) Your confidence will grow as you practice entering programs. When you are ready to fire your kiln, start with simple projects. For instance, small glass pendants are easy to program and can survive even very fast rates. Fire more challenging projects as you gain confidence. If you fire pottery, learn to position witness cones on the shelf so you can monitor them from a peephole. Glass artists should watch the glass through a peephole or kiln window to become familiar with the stages of glass fusing. A firing schedule is only a starting point. If the results are imperfect, then modify the firing schedule. This is not unusual, because your kiln may fire a little differently than the kiln used by the person who designed the firing schedule. Experiment with firing schedules. For example, a potter named Ken fires cone 6 glazes. Through experimentation, he has found that if he programs his kiln to cone 6, he gets pinholes in the glazes. By firing to cone 5 with a 25 minute hold, the glaze is “flawless.” The 25 minute hold bends the cone 6 to 6 o’clock. [Note: Cones are not used in glass firings.] At some point, learn the reason each segment was included in a firing schedule. If you use the pro-programmed Cone-Fire ceramic mode, look at the segments listed in the manual for each cone number, and find out why the segments are included in the program. Why is the kiln programmed to slow down at 1022F? Why does the last segment have a rate of 108F degrees per hour? If you fire glass, find out what a bubble squeeze is. Why does a particular schedule have a slow cooling segment? This information is in the kiln instruction manual, books, or taught at seminars. Understanding the reason for each segment will eliminate the mystery behind a controller and will help you to design your own schedules. ----------- RECENT Q&As Q. Arnold, I have a Paragon manual kiln, and I am trying to keep it at 212F / 100C over several hours, but I am having trouble keeping it at that temperature. I have to sit there and turn it on and off, because it does not have a digital programmer. Any suggestions? A. Prop the lid on the high position of the Prop-R-Vent, which is mounted to the switch box. Turn the bottom switch to Low. Leave the center and top switches Off and the peephole plugs out. This should keep the temperature below 212F. If the temperature goes higher than 212F, occasionally turn off the bottom switch for 15 minutes at a time. Q. When I’m firing my SC-2 jewelry kiln, opening the door to slide in the rack drops the temperature from 1450F to under 1300F. At what point does the timing for a temperature hold begin? Right then? Or when the kiln gets back to 1450F, which is 90 seconds later? A. The Sentry Xpress hold time will begin the first time the target temperature is reached. At that point, the temperature display will start the hold time countdown. At any time, you can watch the countdown timer to check on the amount of time left in hold. ----------- A TEACHER’S STORY: THE POWER OF CREATIVITY Warren Norgaard teaches glass fusing at his Milkweed Arts studio in Phoenix, Arizona. “A few weeks ago, a student approached me and told me that taking my classes had changed her life,” Warren wrote, “that it opened a creative outlet she didn't realize was missing in her life, and that every day she is excited to wake up and see what she can create that day, and she looks forward to our class time all week long. “Hearing this was so overwhelming to me,” Warren continued, “that I’ve heard her words over and over in my head every day since. It was so wonderful to hear and really reaffirmed that I've made the right choices to bring me to this place in life where I can teach something I love, and have a ripple effect on the world around me, no matter how small or large that ripple might be. “I believe in living a life where at the end of each day you can ask yourself, ‘What did I do today to make the world a better place?’ If you don't have an answer, then you need to make a change. This tells me I am making a difference in the world around me, and I am so grateful for the life I have and the passions I have followed which brought me to this place.” ----------- MEMORABLE QUOTE “Raise your words, not voice. It is rain that grows flowers, not thunder.” --Rumi ----------- Interesting people are all around us. A fellow employee here made a “Star Trek” Klingon costume that won an award. His eyes lit up when he told me about the research that went into the fabric, the sash, and the belt buckle. I think of him when I watch “Star Trek.” Another employee reads so many science fiction novels that he maintains a complete database of titles on his home computer. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com / www.facebook.com/paragonkilns PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2015, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||