|

|

|

Kiln Pointers

|

|

|

The Studio Kiln Cord Set |

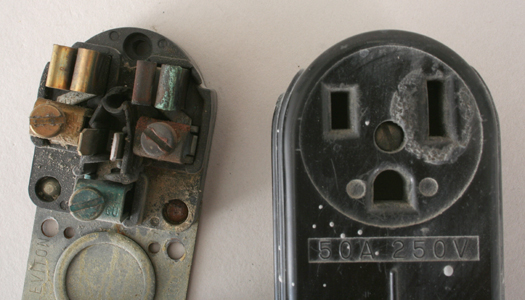

CONTENTS The Studio Kiln Cord Set Recent Q&As: Reason for two elements instead of one in the SC-2; the bubble squeeze; how to turn off elements during a segment A Kiln Story: Focused Attention Memorable Quote News: Paragon Kiln Maintenance Seminar November 6 & 7, 2015 ----------- THE STUDIO KILN CORD SET Most 208 volt 10 or 12 sided kilns are shipped without a cord set and must be direct wired (i.e., an electrician must connect the kiln directly to the circuit without a plug and wall receptacle). That surprises customers, because many of the same kilns, when ordered for 240 volts, include a cord with plug. The 208 volt models require more amperage than the same size 240 volt kilns, because volts x amps = watts. The lower the voltage, the higher the amps needed to achieve the same wattage. When the amperage is higher than the maximum allowed for a receptacle, the kiln must be direct wired. The kiln plug should be tight in the wall receptacle. When the plug and receptacle get too hot, the metal contacts that hold the plug in the receptacle lose their spring tension, causing the plug to pull out easily. The receptacle should be changed when you notice that the plug pulls easily from the receptacle. Also change the receptacle when you see signs of heat damage. Before firing your kiln, check that the cord is not touching the side of the kiln and that the cord insulation is in good condition. As the kiln fires, it is a good habit to place your hand on the kiln’s power cord to check the temperature. It is okay if the cord is slightly warm, but it should not feel hot. Make sure the plug is pushed all the way into the receptacle. Does your kiln have the original factory cord set? Replacing the cord with a lower amperage one will void the warranty and may even burn a wall outlet. ----------- RECENT Q&As Q. Why does your SC-2 and SC-3 have two elements instead of one? A. Both kilns used to have a single element that wrapped around the firing chamber from the left side, across the back, to the right side. Two separate elements in the sides of the current design heat the kilns more evenly than the single element of the previous design. This is because there is less heat build-up toward the back of the kiln. Each element covers only one side of the kiln. Q. Eventually I will know the terminology--like what the hell is a bubble squeeze? A. A bubble squeeze means holding the temperature (not allowing the kiln to get hotter) at the point in a firing where bubbles begin to form in glass. Remaining at that temperature allows the air to escape from between pieces of glass before the air becomes trapped and forms bubbles. Q. When fusing glass, I go up to 825C, soak for 30 minutes, and then drop the temperature to 500C and soak for an hour to anneal. I flash the kiln to drop the temperature below 500C because it just climbs up again once I close the lid. Is there a way to program the controller to stop heating and wait for the temperature to reach 500C, and anneal? A. After the 30 minute soak at 825C, the next segment should have a Full Rate and a target temperature of 500C. Programming a Full Rate will turn off the heating elements during that segment, because the controller will attempt to get to 500C as fast as possible. Since the target temperature is lower than the beginning temperature, the controller will turn off the elements. ----------- A KILN STORY: FOCUSED ATTENTION “When I taught pottery in Texas, the largest part of my night and Saturday classes were doctors and nurses. They said they needed the clay classes to calm down after working in the hospital all day or week. They said it eased their stress almost immediately. Because clay takes all your attention, it pushes aside the day's problems. You can't really think about two things at once. They would come in all jitters and leave all smiles.” --Dannon Rudy ----------- MEMORABLE QUOTE "A feeling of confidence and personal power comes from facing challenges and overcoming them." --Brian Tracy ----------- NEWS: PARAGON KILN MAINTENANCE SEMINAR NOVEMBER 6 & 7, 2015 On November 6 - 7, we are holding a Kiln Maintenance Seminar at the Paragon factory in Mesquite, Texas, which is 20 minutes east of Dallas. The seminar will include hands-on training with kilns at the factory. We plan to include diagnostics with the multimeter, so please bring tools. We believe you will enjoy the seminar, and we hope you can attend. Please contact a customer service representative for further information. Call 800-876-4328 or send an email to amy@paragonweb.com. ----------- At Glass Craft Expo in Las Vegas I told an artist named William, as I admired his glass, “I’ll bet you never get bubbles.” He rolled his eyes and smiled sheepishly. “Yes, I get bubbles.” After a moment he added, “Unless I want them. Then I don’t get them.” Thunder rumbled in the distance for three hours last night. At times it sounded like a steady, reverberating roar. The rain storm was close enough to light up the horizon, but it missed Mesquite as it moved eastward. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com / www.facebook.com/paragonkilns PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2014, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||