|

|

|

Kiln Pointers

|

|

|

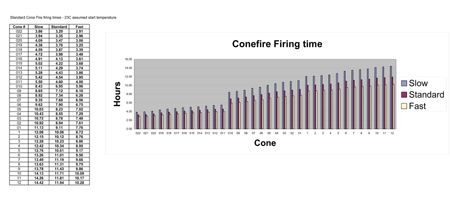

The Expected Firing Times of a Digital Kiln |

CONTENTS The Expected Firing Times of a Digital Kiln Reader Response: Guiding the element pigtails into the firebrick holes; long-handled tools for one-handed operation Recent Q&As: Verifying that Pre-Heat is working in Cone-Fire Memorable Quote News: Introducing the Paragon CS-26 Clamshell Kiln ----------- THE EXPECTED FIRING TIMES OF A DIGITAL KILN Last week a friend called and asked, “How long should a fast 04 Cone-Fire firing take?” I peered at a chart on my bulletin board and said, “Seven hours and 18 minutes.” The chart is published by Orton, the manufacturer of Paragon’s controllers. Cone-Fire is a ceramic firing, but estimating the firing time also applies to other types of firings. “Should the firing take the same time whether it is in a small kiln or large kiln or no matter how heavily it is loaded?” my friend asked. “Yes,” I assured her. “You should be able to predict the total firing time. It should be the same whether you are firing a large kiln or a small one.” “Well, my customers report firing times of Cone-Fire 04 fast at six, seven, and eight hours,” she said. “I wouldn’t want to claim that Orton is wrong, but I know they are.” We laughed. Firing the same program, or schedule, with your digital kiln should take the same amount of time from one kiln to another. (This is assuming that the controllers are the same brand and model.) A temperature controller is a type of calculator. If the controller is programmed to raise the kiln’s temperature by 1000 degrees F at a rate of 200 degrees per hour, the firing will take five hours whether the kiln is empty or heavily loaded, large or small. There are always exceptions, of course. Here are reasons that firing times with the same schedule can differ from one kiln to the next: 1) The room temperature can change the firing time, but usually by only a few minutes. The kiln will take a little longer to reach temperature in a cold room than a warm one, because it is starting from a lower temperature. 2) A kiln that is still warm from a previous firing or warm from Pre-Heat (candling) will take less time to reach temperature than a cold kiln. 3) A kiln that can’t heat or cool as fast as the programmed rate will take longer to fire than the estimated time. (You will get an error code if the slower rate is beyond the controller’s temperature deviation setting.) 4) A heating or cooling segment that has been programmed with a FULL rate will heat or cool as fast as each kiln is capable of rather than at a particular rate. This could make the firing time differ for every kiln that uses that schedule. ----------- READER RESPONSE The last Kiln Pointer is entitled “Cutting the Element Pigtails,” which are the twisted ends of a new heating element. Here are element pointers from two kiln technicians: Norman Brock of San Antonio, Texas wrote, “Whether you are a beginner or a professional at replacing kiln elements, getting the pigtail through the wall to the switch box cabinet on the first try and staying in the original firebrick factory hole can be difficult. “I have found that you can set the new element aside and, using a previous cut pigtail, feel your way carefully from the firebrick side to the cabinet exit. Since you are not managing a coiled element, you can feel your way through the firebrick hole easily. You can even hold a flash light on the kiln wall. Patience will prevent enlarging or misdirecting the original factory hole. “Best wishes,” Norman added, “as we all follow Paragon into the future.” He refers to Paragon’s new president, Todd Lokash. Tony Rodriguez, also of San Antonio, Texas wrote, “Regarding cutting the pigtails, most people use small, inexpensive diagonal cutters. Because they are small, it is very difficult to cut thick wire with them. In 1991 I fell and broke my right wrist, so I was forced to find a way to cut the element pigtails with one hand. I then discovered long-handled, professional tools. This made it possible for me to cut the pigtails easily with one hand. Buy long-handled tools including wire crimpers. They are more expensive but well worth the money.” ----------- RECENT Q&As Q. I am using Pre-Heat in the Cone-Fire mode of a digital controller. How can I be sure that Pre-Heat is actually working? I have programmed 12 hours of Pre-Heat. A. If you are in doubt that Pre-Heat is working, check the kiln's temperature during the first 12 hours. It should remain at 200 degrees F / 93 degrees C. This allows the moisture in the clay to dry safely before firing hotter. ----------- MEMORABLE QUOTE “As we are liberated from our own fear, our presence automatically liberates others." --Marianne Williamson ----------- NEWS: INTRODUCING THE PARAGON CS-26 CLAMSHELL KILN We have just added the CS-26 glass kiln to our website. The top heating elements are held in quartz tubes. You can see the kiln by entering CS26 in the search line of www.paragonweb.com or going here: http://www.paragonweb.com/CS-26.cfm ----------- Last Thursday at noon, the Paragon kiln assembly lines became quiet. The whirring of tools was replaced by music that pounded through the factory during our Mother’s Day lunch. The music mixed with the din of voices from excited, relaxed employees who sat at long tables. The red table cloths were dotted with white plastic cups and plates. On Sunday I presented a birthday gift to Leni, my daughter-in-law, and a Mother’s Day gift to Sandi, my wife. As they removed the wrappings, relatives at the kitchen table exclaimed, “Look at the colors,” “That is beautiful,” “Amazing!” From the wrappings came glass-fused geckos made by artist Karen Pester. Sunlight from the window reflected in the red and blue dichroic glass as we passed the geckos around. We will think about Karen’s beautiful geckos when we see green geckos scurry across the outside of our windows during the hot Texas summer. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com / www.facebook.com/paragonkilns PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2014, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||