|

|

|

Kiln Pointers

|

|

|

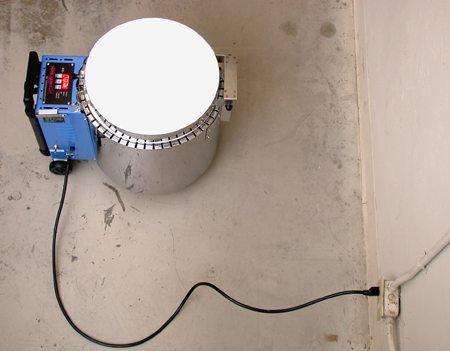

Electric Cord Safety |

CONTENTS Electric Cord Safety Reader Response: Awareness during firing; Wills Point, Texas shop for sale Recent Q&As: Digital kiln transformers; removing knives from furnace at high temperature A Kiln Story: Classroom Clutter Memorable Quote News: Fired Arts and Crafts Magazine Now Online ----------- ELECTRIC CORD SAFETY If you smell burning plastic or hear a crackling noise coming from your kiln, check the cord and the wall outlet. Before firing your kiln, make sure the electric cord is not touching the kiln case. The case gets hot enough to burn the insulation off the cord. If this happens to your kiln, replace the cord--do not repair it with electrical tape. When considering buying a used kiln, check the cord for heat damage. Be sure the plug is pushed all the way into the wall outlet. The kiln should be close enough to the wall that the cord does not strain the wall outlet or the direct-wired connection. A taut cord means the kiln is too far away from the wall. As the kiln fires, occasionally touch the cord. It is normal for the cord to be warm, but something is wrong if it is hot. Do not replace a kiln plug because it does not fit the wall outlet. This can void your kiln’s warranty and cause a safety hazard. Sometimes people replace the cord on older Paragon kilns such as the A-82B because the original cord requires a 4-wire outlet, and their outlet has only 3 wires. This is unsafe. Periodically check the plug and wall outlet for heat damage. To remove the plug from the wall outlet, pull the plug rather than the cord. Disconnect the kiln from the power when you are not using the kiln. Following these guidelines takes only a few extra seconds and will enable you to fire your kiln without worry. The better you understand kiln safety, the more you will enjoy your kiln. ----------- READER RESPONSE In the last Kiln Pointer, John Rodgers wrote, “Touch, sight, and sound are very important when operating a kiln.” Bonnie Staffel of Charlevoix, Michigan wrote, “I might add the sense of smell to the above three. I’ve always had an exhaust fan in the kiln room and very good ventilation. I have been firing kilns since 1947, and my nose tells me when the pyrometric cone is getting close to going down. “If I smell steam in the early stage of firing,” Bonnie continued, “I vent the kiln and hold at 200 degrees F until the peephole passes the mirror test. Around mid fire, I can smell the chemicals fuming. Then near the end, the kiln has a certain odor that tells me to start watching the cones. I also watch the color of the inside of the kiln. “I have been thinking of putting a baby monitor in the garage when I fire as I live in the second story and just passed 90 years of age,” Bonnie added. “That way, to save using the stairs so often, I could then hear if the kiln is clicking normally.” Due to health reasons, Reda Haas is selling ceramic molds, two kilns (one is a Paragon) and supplies. Reda's Angels & More, Wills Point, Texas 75169 ahaas@koyote.com ----------- RECENT Q&As Q. I am installing new elements to convert my digital kiln from 120 volts to 240 volts. Will I need a new transformer? [Some of the small 120 volt kilns can be converted to 240 volts.] A. No. You can use the same transformer, but you will need to rewire it for 240 volts. Please look at a wiring diagram conversion chart. You will need to cut off two wires and add a jumper wire to your transformer. Q. When heat treating knife blades, once the blade reaches certain critical temperatures, it is necessary to open the kiln right away to remove the work piece for quenching. I know opening a hot kiln is a BIG no-no when firing bisque and most clay bodies both for the pots’ sake as well as the bricks in the kiln. Is the same true with knives when I'm firing only to 1500F? A. The bricks are fragile, so the kiln must be loaded carefully to avoid hitting the bricks with tools or kiln furniture. And the elements should be reseated in their grooves if they bulge out. But opening the kiln at heat treating temperatures does not seem to harm the kiln at all. From our experience, the firebricks and elements are not affected by opening the kiln. ----------- A KILN STORY: CLASSROOM CLUTTER John Post of Sterling Heights, Michigan wrote, “What is most likely to catch on fire in the kiln rooms I see in my school district are boxes of scrap paper, yarn, egg cartons, poster board, and piles of kid projects. Some art teachers feel comfortable with clutter. They have no idea that if they reduced the amount of crap in their work environment, they could actually get more work done. A clean organized art room / studio is so much easier to work in. “My kiln room has two ware carts, the kilns, posts, and shelves in it. That's it,” John wrote. “There isn't anything that will catch on fire there. Most of the kilns that I have seen over-fire are pretty melted down inside, but at some point, the elements burned out and the kiln shut itself off without starting the room itself on fire. “The cinder block room my kiln is in isn't likely to catch on fire. It's designed that way for a purpose. The door to the kiln room is a big heavy fire door, too. You would think it would be easy to convince art teachers to be aware of the fire hazards they are creating, but I think the pack rat gene is attached to the creative gene in some people. Every drawer and cabinet in their art rooms are bursting full of so much stuff that they never use. “In my studio at home, before I turn on the computer controller and the kiln vent, I look around and underneath the kiln to make sure there is nothing that will catch on fire there. My kilns are inside a garage that has a roll-up door, and sometimes in the fall, leaves blow in. It's all part of my pre-flight, take-off checklist that I mentally go through when firing my electric kilns.” ----------- MEMORABLE QUOTE “Failures that don't kill us make us bolder and teach us one more way that won't work while opening the door to things that might. School confuses us, so do bosses and families. Go ahead, fail. Try to avoid mistakes, though.” --Seth Godin ----------- NEWS: FIRED ARTS AND CRAFTS MAGAZINE NOW ONLINE Jacquie Morton of Jones Publishing just announced that Fired Arts and Crafts magazine is now online. You can read the articles from your computer at no charge. The magazine is a teaching resource. All projects are set up as lesson plans for K - 12 teachers and ceramists, artists, and studio teachers. http://www.firedartsandcrafts.com/ You can also subscribe to the printed magazine. Twelve issues are on sale for $17.95. ----------- Bonnie's letter reminds of a 1950s house that I lived in years ago. Occasionally, the hall lights flickered. One evening when the house was quiet, I heard a faint crackling noise from a wall outlet in the hallway. Tightening a screw solved the flickering light problem. I hope you are enjoying 2012. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. - Better Designed Kilns 2011 South Town East Blvd. Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 ahoward@paragonweb.com / www.paragonweb.com http://www.flickr.com/photos/paragonkilns |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||