|

|

|

Kiln Pointers

|

|

|

Saving a “Burned Out” Thermocouple |

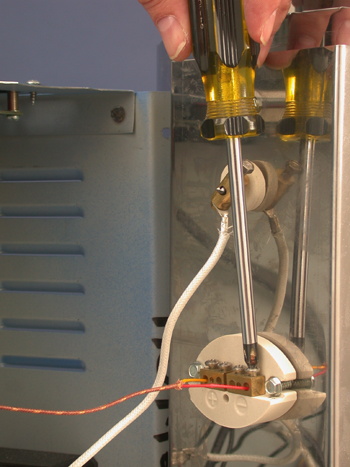

CONTENTS Saving a “Burned Out” Thermocouple Recent Q&As: Front-loading vs. top-loading kilns; silicon carbide shelves in electric kilns A Kiln Story: Unused and Lonely for 15 Years Memorable Quote News: Paragon Kiln Basic Maintenance Seminar ----------- SAVING A “BURNED OUT” THERMOCOUPLE Sometimes people replace perfectly good thermocouples because of a loose or faulty connection at a terminal. So, don’t automatically assume that you have a bad thermocouple when your controller shows a FAIL, TC, or TC2 message. (The message for a bad thermocouple may vary depending on the kiln brand. Please see your instruction manual.) Look at where the thermocouple extends into the firing chamber of your kiln. On the other side of the kiln wall, usually inside a control panel, you should find a connection block. On most kilns, it is an oval porcelain block with four screws. Two screws are for the thermocouple-to-controller wires; the other two are for the wires from the thermocouple. (There are two wires at the end of the thermocouple. They on the opposite end from the tip that extends into the firing chamber.) An over-tightened screw can break a thermocouple wire. You won’t be able to see the broken wire, because it will be hidden under the connection screw. If you can remove the thermocouple by loosening only one screw, then you know the wire under the other screw was broken. Sometimes you can repair the thermocouple by pushing it 1/8” closer to the connection block so that the shorter wire that broke can reach the connection. This allows you to install both wires under the connection screws. If you do this, make sure the thermocouple still extends into the firing chamber by four times its diameter. Note: Some kilns, such as the SC-2, do not have a connection block. The thermocouple and wires are one unit. This Kiln Pointer does not apply to that type of thermocouple. ----------- RECENT Q&As Q. What is the difference between loading ceramics in a front-loading kiln and a top-loading kiln? A. Smaller, lighter pieces are usually loaded in the front of the kiln near the door or on the bottom. This is because these are the cooler areas of the kiln. Load heavier pieces near the back wall of a front-loading kiln. Q. I've read that the light-weight silicon carbide shelves are bad for electric kilns. Please share your thoughts. A. Silicon carbide shelves are used mostly in gas kilns instead of electric, because the shelves can conduct electricity. But they do not damage electric kilns. They are lighter than cordierite shelves and more expensive. If you use silicon carbide shelves, repair any element that is bulging out of a groove. ----------- A KILN STORY: UNUSED AND LONELY FOR 15 YEARS Lynne Fear of Londonderry, Vermont wrote, “I bought my kiln back in the 80's when I lived in New Jersey. The kiln was then stored in a basement in Cape Cod, Massachusetts for 11 years, unused and lonely, and for four years in an unheated garage in Vermont. “When we moved from New Jersey,” Lynne continued, “I filled a big black garbage bag with packing foam popcorn, stuffed it inside the kiln, and put packing tape over the top to keep the lid closed. So the kiln sat for 15 years with the big black bag inside. Just recently, I moved it to the basement in Vermont, took out the bag, called an electrician, and went to work removing the tape that was stuck, very stuck, with Goo Gone (which was a BIG job), and plugged it in! The kiln started right up. By some miracle I still have my owners manual, so I followed the instructions on starting a kiln that's been in an unheated garage, in this case, for 15 years! “The kiln, shiny and beautiful, is working just fine, and my seven grandchildren are having a wonderful time painting tiles and glazing their clay creations. I am so glad I didn't listen to my husband who said, at least once a year, ‘Why don't you sell that thing?’” ----------- MEMORABLE QUOTE “I didn't see it then, but it turned out that getting fired from Apple was the best thing that could have ever happened to me. The heaviness of being successful was replaced by the lightness of being a beginner again, less sure about everything. It freed me to enter one of the most creative periods of my life.” –Steve Jobs ----------- NEWS: PARAGON KILN BASIC MAINTENANCE SEMINAR We are holding a Basic Kiln Maintenance Seminar on February 10 - 11, 2012 here at the Mesquite factory. The seminar fee is $105. For more information and to register, please call 800-876-4328 or 972-288-7557 and ask for customer service. Or send inquiries to ttrice@paragonweb.com . ----------- Shelia, who works at Paragon, recently found a creative use for discarded glass. She crushed a brown beer bottle and fired the pieces in a 3” tile mold and a face mold. Then she fused the face onto the tile. She used the Paragon QuikFire 6 for all three firings. You can see the results here: www.facebook.com/paragonkilns Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com / www.facebook.com/paragonkilns PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2011, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||