|

|

|

Kiln Pointers

|

|

|

How to Combine Two Digital Firings |

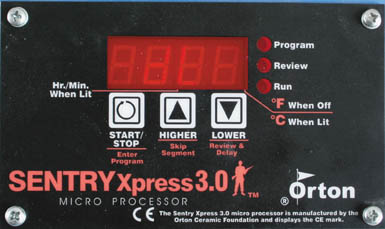

CONTENTS How to Combine Two Digital Firings Recent Q&As: Slow cooling and element life; high firing and element life A Kiln Story: The Clogged Kiln Vent Memorable Quote ----------- HOW TO COMBINE TWO DIGITAL FIRINGS A customer asked how to combine Firing #1 and Firing #2 into one firing: Firing #1 Segment 1: Ramp 650 F per hour to 1000 F. Hold for 2 hours. After the kiln has cooled down to 200 F, begin Firing #2. Firing #2 Segment 1: Ramp 650 F per hour to 1000 F. Segment 2: Ramp 380 F per hour to 1525 F. Hold for 2 hours. The Combined Firing Segment 1: Ramp 650 F per hour to 1000 F. Hold for 2 hours. Segment 2: Ramp at Full to 200 F, no hold. Segment 3: Ramp 650 F per hour to 1000 F, no hold. Segment 4: Ramp 380 F per hour to 1525 F. Hold for 2 hours. In the combined firing, the segment 2 ramp is Full. Since segment 2 is a cooling segment, a Full ramp will turn off the heating elements. They will not turn back on until segment 3 begins. A heating segment Full rate means heat as fast as possible. The elements will stay on continuously during that segment. A cooling segment Full rate means cool as fast as possible. The elements will remain off for that segment. ----------- RECENT Q&As Q. In an earlier newsletter, you wrote that slow cooling can reduce the life of the heating element. Would this apply to the schedule I am following for wax burnout, which uses a Full rate for cooling? A. No, because the cooling segment has a Full rate, which means the elements are turned off during that segment. Full means the controller will try to reach the cooling segment as fast as possible, and it does that by turning off the elements. Q. You also wrote that firing high adds wear to the heating elements. Is 1350 F considered high firing? And is it apt to add wear to the element? A. Reaching a temperature of 2200 F and higher wears the elements faster than firing to low temperatures, such as 1350 F. At 1350 F, your elements will last a long time unless they are damaged by exposure to foreign materials. ----------- A KILN STORY: THE CLOGGED KILN VENT John Post of Sterling Heights, Michigan wrote, “A bond proposal passed in 2003 to build additions onto the 30 elementary schools in my district. A wing that contained a science room, an art room, and a music room was to be added to each school. “The head of the elementary art department didn't accept input into how the kiln rooms should be laid out. Neither did the contractors. I couldn't find anyone to listen to a few simple suggestions. “They botched up the design of the electric kiln vent exit on the first set of 10 schools,” John explained. “The contractors had the 4 inch duct exit the building 6 feet off the ground, covered with a thin louvered vent. When I saw this I told my principal, ‘The kids are going to bust the louvers off the vent after school and cram stuff down the vent.’ As I predicted, within three months the vent cover had no louvers. Maintenance installed a second thicker one. The kids broke that one too. Then maintenance finally put a heavy steel cage over the 4 inch vent. “Today, I noticed that the ductwork coming from under the kiln had deteriorated,” said John. “When I opened up the kiln vent ductwork, I found a water bottle, a cell phone belt holster with phone book, rocks, pens and pencils, and an asthma inhaler. I'm surprised that air could even make it out of the vent these last 5 years. All of it was dusty, dirty, and corroded. “On the next 20 school additions, the kiln vent exits the building at about 12 feet off the ground, so someone finally figured it out.” Perhaps other schools will learn from John's story. Feel free to send your kiln anecdotes. Use the email address below. ----------- MEMORABLE QUOTE “Be prepared to reinvent yourself every year. Imagine starting over with no limitations or encumbrances.” --Brian Tracy ----------- A friend named Eddie told me about his 90-pound Akita dog. One day Eddie noticed a piece of plastic pipe lying in his yard and wondered where it came from. Teeth marks decorated the length of plastic. One end was chewed ragged. Then he realized that his Akita had dug up part of the buried sprinkler system. “People wonder why I don’t find him a home,” Eddie said thoughtfully. To answer that question, Eddie told me about a little girl who stops outside his fenced yard every day to greet the Akita. One day Eddie saw the dog lean over the fence with a paw on each of the girl’s shoulders while she wrapped her arms around the dog. In his Texas drawl he added, “That’s why I can’t bring myself to find my dog a home.” Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com / www.facebook.com/paragonkilns PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2011, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||