|

|

|

Kiln Pointers

|

|

|

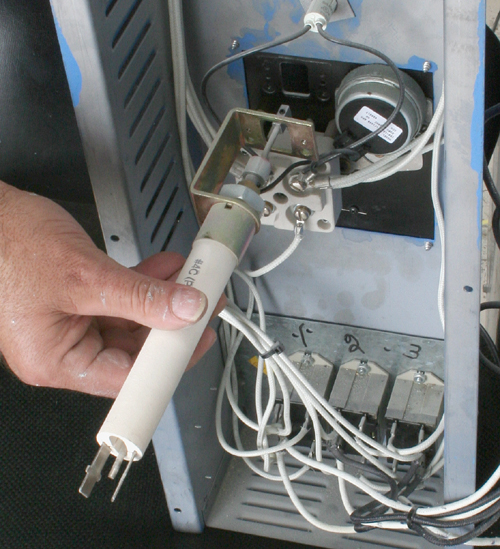

Replacing the Kiln Sitter Tube |

CONTENTS Replacing the Kiln Sitter Tube Reader Response: A reader shares a winter scene Recent Q&As: Programming a cooling rate; measuring a kiln’s firing chamber depth Memorable Quote News: New Kiln Sitter / Auto-Cone Manual ----------- REPLACING THE KILN SITTER TUBE Replace the porcelain tube assembly when the movement of the sensing rod becomes sluggish or when the sensing rod is bent. Be sure the replacement tube assembly is the correct length for you kiln. (You can download a new manual that includes photos to go with these instructions. Please see the News section below.) 1) Disconnect the power to the kiln. 2) Make sure there is no cone or firing gauge in the Kiln Sitter. 3) Remove and save the screws at the side of the switch box that hold it to the kiln and remove the box, carefully pulling straight out. You may need to prop the box on a chair or other object as you lean the box against the kiln. Leave the wires attached to the Kiln Sitter. While you have the Kiln Sitter out, it is a good idea to clean the back side of the Kiln Sitter with compressed air. 4) Remove the 2 screws holding the guide plate to the front of the Kiln Sitter. 5) Remove the guide plate. 6) Remove the 2 screws that hold the porcelain tube bracket to the Kiln Sitter. 7) Remove the porcelain tube and bracket. 8) (Steps 8 and 9 are for Dawson tube assemblies. Skip steps 8 and 9 for Orton tube assemblies, which have the tube assembly bracket permanently attached.) Remove the nut holding the porcelain tube assembly to the tube assembly bracket. 9) You will see a notch on the top of the new tube assembly. Align that notch with the pin on the tube assembly bracket. Install the washer and nut. (The washer goes under the nut on the front of the tube assembly bracket.) 10) Remove the release claw from the old porcelain tube and install it on the new tube. 11) Install the porcelain tube bracket to the Kiln Sitter (the reverse of step 6). 12) Reinstall the guide plate to the front of the Kiln Sitter. Tap the guide plate from side to side until the rod is centered in the porcelain tube. The easiest way to adjust the guide plate is to loosen the screws so that they barely hold the guide plate in place. Then gently nudge the plate sideways. The guide plate is more difficult to adjust if you loosen the screws completely. 13) After the rod is centered, securely tighten guide plate screws. 14) Reinstall the switch box. Arrange the wires so they do not interfere with the locking slide that trips when the weight drops. (You can see how the locking slide works by lifting the weight, pressing the plunger, and then dropping the weight.) Also, arrange the wires inside the switch box so that wires do not touch the element connectors or the kiln case. Important: Check the Kiln Sitter adjustments shown on pages 5 - 7 of our new manual before firing the kiln. ----------- READER RESPONSE Jamie Gray of Calgary, Alberta, Canada wrote, “Here's what you're NOT missing in Mesquite: icy roads, frost-bitten fingers, scraping the car windshield. However, I will share a most beautiful scene that just occurred. A gorgeous male pheasant wandered by, sauntering along and picking seeds out of the flower bed just outside my office window. I was mesmerized. It was a scene straight out of Currier and Ives.” Jamie added that The Calgary Warm Glass Guild is now on Facebook. You can also find Paragon Kilns there. ----------- RECENT Q&As Q. Programming a cooling in Ramp-Hold seems confusing. A. Program a cooling segment the same way you program a heating segment. Only instead of entering a higher temperature, enter a lower one. The Sentry and Bartlett controllers automatically interpret that as a cooling segment. Heating the kiln at a rate of 9999 leaves the elements turned on, just like turning a switch to High. Cooling at a rate of 9999 turns the elements off. You will not hear the relays clicking during a 9999 rate. Learn your kiln's natural cooling rate. Programming a cooling rate that is faster than that will result in an error message. A cooling rate of 9999 puts the kiln into a "free fall," which is the kiln's natural cooling rate. Error codes that appear when the controller cannot heat or cool at a programmed rate are turned off for segments that contain a 9999 rate. Q. How is depth measured in a kiln? A. The interior depth is always front-to-back for a kiln with a door and top-to-bottom for a kiln with a lid. For outside kiln dimensions, depth is the distance from the front of the kiln to the back. ----------- MEMORABLE QUOTE "All improvement in your life begins with an improvement in your mental pictures." -- Brian Tracy ----------- NEWS: New 24-page Kiln Sitter / Orton Auto-Cone Manual We have just loaded a new 24-page Kiln Sitter / Orton Auto-Cone instruction manual to our website. Please visit www.paragonweb.com and click on Support, and then Instruction Manuals from the drop menu. Scroll down the list of manuals to Kiln Sitter / Auto-Cone Instructions. Or paste the link into your browser: http://www.paragonweb.com/files/manuals/IM239_Kiln-Sitter-Paragon-Kilns.pdf ----------- Christmas carols remind me of my childhood in Calgary, Alberta. Our elementary school gathered in the auditorium on Fridays and sang carols together. We sat cross-legged on the polished wooden floor. I can still hear those voices reverberating through the room. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2009, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||