|

|

|

Kiln Pointers

|

|

|

How To Do a Slow Cooling |

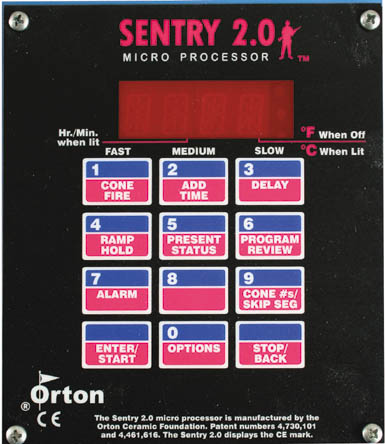

CONTENTS How To Do a Slow Cooling Recent Q&As: Cooling rate and the kiln vent; full-fuse and tack-fuse in the same kiln load Memorable Quote News: New Paragon videos ----------- HOW TO DO A SLOW COOLING Slow cooling can alter the materials you are firing. Slow cooling softens high-carbon tool steels, anneals glass to prevent stress fractures, and changes the color of some ceramic glazes. You can slow down the cooling even if you do not have a digital controller on your kiln. Slow Cooling in Ramp-Hold Mode In the Ramp-Hold mode of your digital controller, you can start and stop the controlled cooling at any point on the way down to room temperature. Each controlled cooling period will require at least one separate programming segment. So, if you wanted two controlled coolings on the way to room temperature, you would need at least two segments. For each cooling segment, enter a target temperature that is lower than the starting temperature of that segment. On most brands of controllers, this will automatically control the cooling rate. Slow Cooling in Cone-Fire Mode Cone-Fire mode is available on ceramic kilns equipped with the Sentry 2.0 controller. After you enter the hold time, COOL will appear in the display. Enter a cooling rate between 1 degree and 180F / 82C per hour. Slow cooling at that rate begins after reaching the cone firing temperature and ends at 392F / 200C. Slow Cooling with a Switch-Operated Kiln Use a pyrometer to watch the kiln’s temperature. When the kiln reaches the temperature range where you need to slow the cooling, turn the switches to medium or low. Adjust the switches to maintain the desired cooling rate. This is a good time to catch up on reading if you need to stay with your kiln for an extended period. ----------- RECENT Q&As Q. During a controlled cooling, does a digital kiln fire down at the same speed whether the kiln vent is on or off? A. During a controlled cooling, a digital kiln turns on the elements intermittently to maintain the programmed firing rate. The slower the programmed rate, the more often the elements turn on. If the vent causes the kiln to cool faster than normal, the elements will turn on more frequently. So, the controller will maintain the same cooling rate whether or not you run the downdraft vent. Q. In the first fusing classes I took, the store did a tack fuse and a full fuse in one kiln load using multiple kiln shelves. What temperature is required for this technique? A. You can do this in a glass kiln that has a fairly deep firing chamber and top elements, such as the GL-24AD. Fire two shelves stacked vertically and separated by posts. The glass on the top shelf will reach full-fuse; the glass on the bottom shelf will reach tack-fuse. You will need to experiment with post height, firing speed, and temperature, all factors that will affect the results of the firing. The ideal way to experiment is to check the glass visually before it begins to fuse. (You will need firing safety glasses.) You might also achieve full-fuse / tack-fuse in a ceramic kiln with side elements. That, too, will require experimentation. The glass on the outer edges of the shelves tends to fuse more than pieces in the center of the shelves, especially with large studio kilns. ----------- MEMORABLE QUOTE "If one is master of one thing and understands one thing well, one has at the same time, insight into and understanding of many things." -Vincent Van Gogh ----------- NEW VIDEOS I have loaded new videos at Paragon’s website. Go to www.paragonweb.com and click on the video link, which is along the left side of the page. http://www.paragonweb.com/videos.cfm If you prefer, you can also watch the new videos at Youtube.com. Enter Paragon kilns at the Youtube search line. ----------- Last Saturday morning, my wife and I took a walk through our neighborhood. The trees in front of several houses were covered with strands of toilet paper, which fluttered in the breeze. It was the work of rival school football teams. Then we passed a house with a Marine flag in front. Near it was a white sign with a blue star. The sign was a reminder that a war is raging on the other side of the planet--so far away, yet so close to our quiet Mesquite neighborhood. Undoubtedly some of you have a loved one in a combat zone. On this Veterans Day, I wish them a safe return home and a joyous reunion. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2009, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||