|

|

|

Kiln Pointers

|

|

|

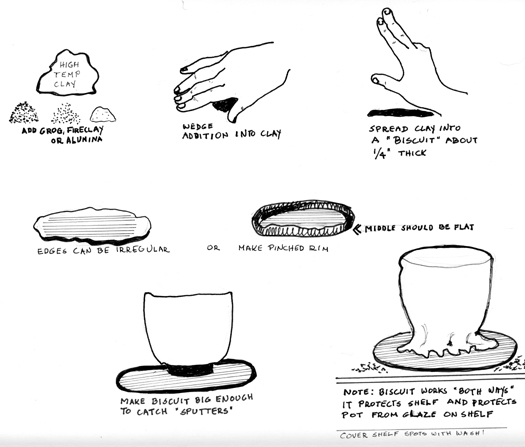

Clay Biscuits For Runny Ceramic Glazes |

CONTENTS Clay Biscuits For Runny Ceramic Glazes Recent Q&As: Four factors in choosing a kiln; viewing witness cones; witness cones and a digital controller; the small gouges in firebricks Memorable Quote News: Basic Kiln Seminar October 2 – 3, 2009 ----------- CLAY BISCUITS FOR RUNNY CERAMIC GLAZES By Lili Krakowski What can you do about running glazes? TEST, TEST, TEST. Never put a new glaze on a pot before testing it first on test tiles of several clay bodies in several locations in your kiln. Never apply glaze from a new batch before testing it first. (Mixing errors are made!) Make pancakes or biscuits of grogged, quite refractory clay, and set tests on them. Not an itty-bitty biscuit, but one large enough to act as saucers. Designate a worn or uncleanable shelf TO TESTS ONLY. And for those who love double application, test that too. Oh, the messes created by one glaze over another, fluxing each other! Making Biscuits (Please see Lili’s accompanying drawing.) 1) Add grog, fireclay, or alumina to the high temperature clay. 2) Wedge the ingredient from #1 above into the clay. 3) Spread the clay into a “biscuit” about 1/4” thick. 4) The biscuit edges can be irregular, or you can make a pinched rim. The middle of the biscuit should be flat. Make the biscuit big enough to catch glaze sputters. Note: Biscuits work both ways: They protect a kiln shelf from glaze, and they protect pots from glaze that has embedded into a shelf. (Thanks, Lili, for the pointer on biscuits and for the drawing that you graciously included. --Arnold) ----------- RECENT Q&As Q. I am considering buying my first kiln. The choices and information on kilns seem overwhelming. A. Choosing a kiln becomes simpler when you narrow the search with these four factors: 1) The size of the electric circuit in your studio. Will you use the circuit already wired, or will you have a new one installed? Your kiln choice will be limited by the number of amps available. 2) The size of the kiln. Estimate how much firing chamber space you need. How big are the pieces you will fire? How often do you want to fire? 3) Front loading or top loading. 4) Firing temperature. Narrow the kiln selection search with those four factors, and make a list of kiln models that you are considering. Then compare those kilns in greater detail. Try out the competing controllers using online interactive demos. That is like driving a car before you buy it. Q. I lose shelf space when I keep a clear line of sight from the peephole to the cones and the element behind them. (This question refers to positioning the witness cones inside the kiln.) A. You need to see only one set of witness cones. You don't have to see them on every shelf. Q. I'd like to add a hold on my digital controller to heal glaze pinholes in my next cone 5 firing. Should I fire to cone 4, add hold time, and stop the firing when I see the cone 5 witness cone drop? A. Yes. Fire to cone 4 with hold, and turn off the kiln when the cone 5 witness cone drops. Write down how long the kiln was on hold. Then the next time you fire, program that much hold time. Q. The firebricks in my kiln have what look like gouges, or small holes, on the surface. The depth of the holes is 4 – 8 mm (1/3 inch). Is there anything wrong with the kiln? A. Do not worry about the holes. A surface gouge with a 4-8 mm depth is normal for a firebrick. The bricks are porous. Those gouges were formed when the bricks were manufactured. Firebricks can withstand tremendous stresses during firing. They expand and contract; they cycle from red hot back down to room temperature repeatedly. Few other materials are put to such a severe test. Consequently, cracks and other cosmetic flaws form in the surface and are unavoidable. ------------- Paragon’s website now has 581 FAQs. You can find answers to questions by entering key words in the search line at www.paragonweb.com. Example: A search for paper clay brings up this answer: http://www.paragonweb.com/faqinfo.cfm?faqid=618 ----------- MEMORABLE QUOTE “My grandmother, who has taught china painting for 60 years, coached me during my first firing. I treasure the memory of that moment of my life with her.” --Darcy Giesseman ----------- NEWS: BASIC KILN SEMINAR OCTOBER 2 – 3, 2009 Paragon will hold a 1-1/2 day Basic Repair and Maintenance Seminar at the Paragon kiln factory in Mesquite, Texas. The seminar will cover basic electricity, kiln electrical installation, the multi-meter, switch replacement, electrical troubleshooting, element replacement, the Kiln Sitter, electronic kiln diagnostics, and more. Please call for more information. ----------- Last Saturday I was on the roof of my two-story house replacing the chimney siding. The sunscreen on my face looked like war paint. As I crouched on a scaffold, my safety glasses slid off the roof and into the back yard. The next day I retrieved the glasses. One of my dogs had neatly chewed off the stems, which were scattered in the grass. I hope you are enjoying your summer. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2009, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||