|

|

|

Kiln Pointers

|

|

|

How to Plug the Glass Window on a Kiln |

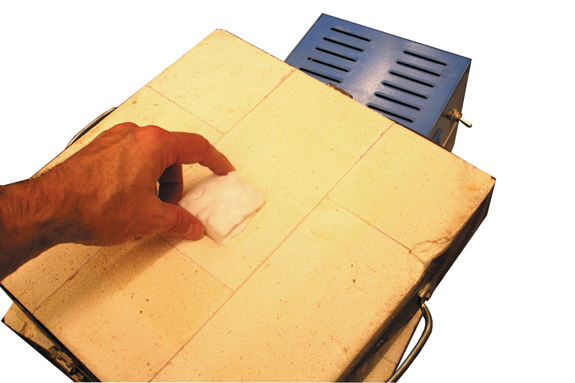

CONTENTS How to Plug the Glass Window on a Kiln Recent Q&As: TCR error message; Converting degrees C to degrees F Memorable Quote ----------- HOW TO PLUG THE GLASS WINDOW ON A KILN Many small kilns can be ordered with a high-temperature glass window, which allows you to see inside the kiln. This is especially helpful in fusing glass, because you can judge just when to turn off the kiln. The windows are typically 1” x 3” or 2” x 2”, which is larger than a peephole. Some of the kilns that have the window are designed to fire glass or pottery. (See the electrical data plate on your kiln for the maximum temperature rating.) But to fire pottery in such a kiln, you may have to plug the window. Recently I ran four tests of an empty digital Caldera with window in the lid. All tests were with a single segment, full rate, to 2350 degrees F. Test #1: In the first test, I left the glass window unplugged. The kiln stalled and flashed FtL at around 2119 F. (FtL = Firing Too Long, meaning the kiln couldn't reach 2350F.) Test #2: In the second test, I plugged the 2" x 2" lid cavity under the window with ceramic fiber. I filled the entire 2" x 2" lid cavity so the fiber was flush with the firebrick inner lid surface. The kiln reached 2350F in 2 hours, 50 minutes. Test #3: In the third test, I plugged the 2" x 2" opening with only a 1/2" layer of ceramic fiber. The kiln slowed down and finally flashed FtL at 2339 F. Test #4: In the fourth test, I fired the Caldera with a solid firebrick lid without the window. The kiln reached 2350F in 2 hours, 47 minutes. ----------- RECENT Q&As Q What causes the thermocouple TCR error message on a digital kiln? A There are three reasons: 1) The main one is reversed thermocouple wires. 2) A false temperature reading (such as -300 degrees) resulting from a defect in the temperature measurement circuit or memory corruption. 3) Operating the kiln in a cold environment where the thermocouple is cold (32F or below) and the controller board temperature is much warmer (70F or above). Orton recently enhanced the software to eliminate TCR from this condition. Q I am casting 3” thick glass and wish to set cooling rates of less than one degree Celsius. Is this possible with the Sentry 2.0? A Since 1 degree F is .55 degrees C, set the controller for degrees F. Then convert your degrees C program to degrees F. Use formula 1 below to convert a firing temperature. Use formula 2 to convert a change in temperature, or rate. 1) Firing temperature (i.e. "Fire to 1600F." 1600F = 871C) (C x 1.8) +32 = F (F - 32) divided by 1.8 = C 2) Firing rate or temperature change (i.e. "Fire at 200F per hour" or "Fire 200F hotter." 200F = 111C) C x 1.8 = F F divided by 1.8 = C ----------- MEMORABLE QUOTE “There is more treasure in books than in all the pirate's loot on Treasure Island ... and best of all, you can enjoy these riches every day of your life." -- Walt Disney ----------- Let me know if we are missing an especially good title from our kiln firing reading list: I picked up the reading habit from my parents. When I was 13 years old, I spent part of my summer vacation reading paperback novels. I averaged one a day. It was an escape from the sweltering heat of North Africa. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd., Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 / ahoward@paragonweb.com / www.paragonweb.com http://twitter.com/arnoldhoward / www.facebook.com/arnoldhoward PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2009, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||