|

|

|

Kiln Pointers

|

|

|

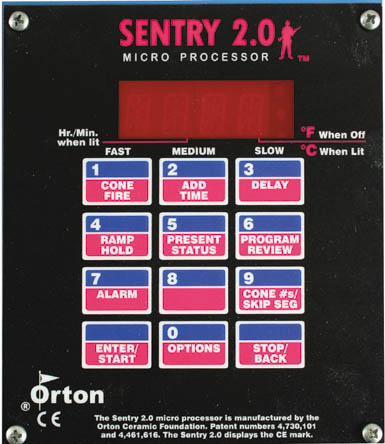

The Basics of a Temperature Controller |

CONTENTS The Basics of a Temperature Controller Reader Response: the smoking kiln; the first firing; kiln songs Recent Q&As: unplugging a kiln; compensating for an inaccurate pyrometer ------------- THE BASICS OF A TEMPERATURE CONTROLLER Some controllers are more complicated than others, but they all do three things. Once you understand this, you can understand any digital controller. 1) A controller fires at a controlled heating rate, or speed. This is usually measured in degrees of temperature change per hour. (This is like measuring the speed of a car in miles per hour.) At a rate of 100° per hour, it would take 10 hours for the kiln to reach 1000°. 2) A controller fires to a target temperature. This is the same as turning the dial on an oven to 350 degrees to bake potatoes, except the temperature for glass and ceramics is much higher. 3) After the controller reaches the target temperature, it can also hold, or soak, at that temperature. This is the same as the oven baking potatoes at 350 degrees for 45 minutes. On a controller, that would be called a 45-minute hold. The controller fires in segments, or stages. Each segment has a firing rate, target temperature, and hold. After the controller has fired the last segment, it turns off power to the heating elements. ------------- READER RESPONSE Last week’s Kiln Pointer included a story called “The Smoking Kiln.” Newy Fagan of Ocklawaha, Florida wrote, “I was at a glass event once, when we smelled something burning. It was the kiln instructions in the plastic bag that were not removed when the instructor turned on the kiln for a bead class. No names mentioned, but another case in point for the ‘Smoking Kiln’ saga.” Carol Kothmann of Mason, Texas wrote, “For the first few firings, I had to have my husband around for moral support. I had never fired a kiln, nor even seen one used. My husband had no experience either, but somehow it felt much better to have him with me. I found it amazing to realize the amount of heat required to create the glowing interior. My husband was not so easily impressed as he had taught welding. Hot things don't bother him.” Angela deMott of Santa Monica, California wrote, “Peepholes, peepholes that need people, are the luckiest peepholes, in the world... “Jeepers, creepers, where'd ya get those peepholes...” ------------- RECENT Q&As Q. Would unplugging the kiln erase the digital programs? Should the kiln be unplugged when not in use? A. Yes, you can unplug the kiln. The digital programs will stay in memory even without power. For safety, you should unplug the kiln or disconnect the power when the kiln is not in use. Q. I use a portable analog pyrometer with a thermocouple inserted into one of the peepholes. When cone 6 is down and cone 7 is starting to bend, the pyrometer reads 1960F, although Orton says the kiln is between 2260 and 2300 according to the witness cones. I would like to know how to make the pyrometer more accurate so I can use it to hold-soak to get crystals. A. Because of the cone tests, you know the pyrometer reading is 300 F. too cool in the cone 6 - 7 range. Merely add 300 degrees to the readings in that temperature range. Make sure the thermocouple is inserted the same distance into the firing chamber and in the same peephole with each firing so that you will get consistent readings. Also, check that the thermocouple lead wire connections are tight. Q. While this is fine for knowing when I am close to cone 6, how consistent would the error be at other temperatures? Is it likely that the pyrometer will be consistently 300 degrees low throughout the firing (at least after reaching 1000), or does the discrepancy vary at higher or lower ranges? A. Your pyrometer reads 300 degrees too cool in the cone 6 range. But in other temperature ranges (i.e. cone 04), the readings may not remain consistently 300 degrees off. For this reason, you should test the pyrometer with cones for the other temperatures where you will do a soak. ------------ Last Saturday my wife’s uncle, Mark, was on life support at Baylor Medical Center after undergoing surgery. In late afternoon, a nurse switched off the array of monitors and respirator. Computer screens went black, the indicator lights on machines faded, and the mechanical breathing went silent. At a moment like that, one realizes that most of our concerns are meaningless. It is friends and family that really matter. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd. Mesquite, Texas 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 ahoward@paragonweb.com / www.paragonweb.com ------------- PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2008, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||