|

|

|

Kiln Pointers

|

|

|

How a Digital Kiln Turns on the Elements |

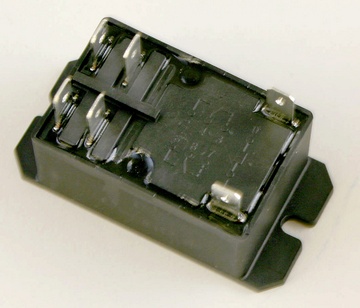

CONTENTS How a Digital Kiln Turns on the Elements Reader Response: more on fear of kilns Recent Q&As: the stages of glass fusing; a digital kiln error message ------------ HOW A DIGITAL KILN TURNS ON THE ELEMENTS One of the most common questions I’ve heard is, “My kiln is making a clicking noise. Is there something wrong with it?” The clicking is the normal sound of the relays turning the elements on or off. A digital temperature controller uses one or more relays to turn on the heating elements of an electric kiln. The controller operates the relay by sending it a 12-volt signal. The most widely used relay in digital glass and pottery kilns is the mechanical relay. The 12-volt signal from the controller turns on a small electromagnet inside the relay, which pulls electric contacts together. Power flows to the heating elements through the contacts. Each time the relay receives the 12-volt signal, the contacts come together and make a clicking noise. Another type of relay is the solid-state, which in theory outlasts the mechanical relay. However, the solid-state relay is more prone to fail due to overheating than is the mechanical relay. And when the solid-state relay fails, the heating elements stay locked on, overfiring the kiln. When the mechanical relay fails, on the other hand, the heating elements usually turn off. A third type of relay is the mercury relay, noted for long life. It outlasts the other types of relays; its service life has been measured in millions of on/off cycles. When it fails, the elements remain off. We have used the mercury relays for years in our larger pottery and glass kilns with outstanding results. Optional factory-installed mercury relays are available for many of our studio-size kilns. We have found that glass kilns place more wear on relays than do pottery kilns. This is because the long firing cycles for thick glass, especially through the annealing range, require many hours of frequent relay clicking. Pottery kilns usually fire to a temperature and shut off. ------------- READER RESPONSE Carole Dwinell of Martinez, California wrote, “I had to laugh at your latest newsletter about fear of kilns. I had my kiln for more than a year and a half before I got up enough courage to fire it. Now it's simply no big deal. (Well, almost. There's still a minor tremor here and there.) I've gone from having almost everything break in the school kiln to NOTHING, absolutely nothing, failing at home, so I'm totally stoked!” RECENT Q&As Q. I make fused glass pendants but can never seem to get the layers of glass to have a smooth edge. The top smooths out and it looks great, but you can tell there are multiple layers by the edges. They just don't seem to meld into a smooth, rounded edge. What am I doing wrong? A. Glass goes through many stages of fusing as the kiln temperature rises. At first, separate pieces of glass soften and stick together while still retaining their original edges. As the temperature goes up, the glass gradually softens further, and sharp edges become rounder. Finally, separate layers merge together into one smooth surface. The easiest way to fuse glass is to watch it as it goes through the stages of fusing. I fused glass in Paragon's first glass kilns, which had infinite control switches. The digital controllers came only years later. I watched the glass by cracking the door open a quarter inch as the kiln fired. Be sure to wear firing safety glasses and protective clothing if you open a hot kiln. Open the door just enough to see inside the kiln. Look for a couple of seconds, and then close the door. Begin checking the glass after the interior turns orange. Depending on how fast the kiln fires, check the glass every five or ten minutes. When the glass fuses exactly the way you desire, write down the temperature shown in the controller display window and turn off the kiln. The next time you fire that type of project, program the kiln for the temperature you noted. Q. The controller on my Paragon SC-2 jewelry kiln flashes FTL, but only when I include a controlled cooling. What is happening? A. FTL means “firing too long.” The kiln is taking too long to fire, perhaps because an element burned out. But “firing too long” applies to cooling as well as to heating. FTL can appear if you program a segment for slow cooling and the kiln is taking too long to cool. Program a slower cooling rate. FTL will also appear if you program a cooling segment target temperature that is below or even close to room temperature. ------------- Last weekend at Glass Craft and Bead Expo in Las Vegas, Leslie Perlis, a glass artist of San Diego, California, stopped by Paragon’s display booth. She gave me a small box of candy. After she left, I offered a candy to Laura Lemons, another employee. Laura asked, “What kind of candy is it?” Inside the box were three small chocolates nestled in paper. Laura picked one up and said, “Is this candy or glass?” It was only then that I realized the candy was actually made of fused glass. Thank you, Leslie. Thank you, With best wishes, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd. Mesquite, TX 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 ahoward@paragonweb.com / www.paragonweb.com PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2007, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||