|

|

|

Kiln Pointers

|

|

|

The Shut-Off Temperature in Cone-Fire Mode |

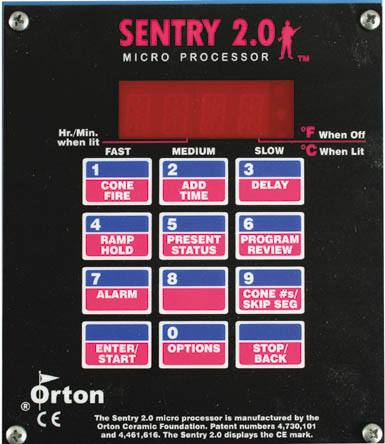

CONTENTS The Shut-Off Temperature in Cone-Fire Mode Archived Questions & Answers A Glass Fusing Pointer Recent Q&As: Firing moist greenware; When a kiln stops making a clicking noise; A firing schedule for glass slumping molds THE SHUT-OFF TEMPERATURE IN CONE-FIRE MODE Digital controllers sometimes do little things that baffle people. An example is the shutoff temperature in Cone-Fire mode. Digital ceramic kilns in the U.S. have two firing modes: Cone-Fire and Ramp-Hold. Cone-Fire mode is based on the pyrometric cone numbers used in ceramic firings. Sometimes the shutoff temperature in Cone-Fire mode varies from one firing to another for a given cone. This is due to the controller’s automatic heat-work calculation that is built into Cone-Fire mode. The firing rate for the last segment of a Cone-Fire program is 108 degrees F / 60 degrees C per hour. If the kiln fires at that rate during the last hour, the shut-off temperature will match the temperature on Orton's cone chart in the 108 degree F column. (You can view the cone temperatures in the controller’s Cone Table. Instructions vary depending on the brand of kiln. For the Sentry controller, press 9 from Idle.) If the kiln is firing slower than 108 degrees F / 60 degrees C during the last hour, the controller will compensate by shutting off at a slightly lower temperature. This is because firing slower does the same amount of heat work at a lower temperature as firing faster to a higher temperature. Your kiln may be firing slower due to element wear, low voltage, or a heavier load of ware than usual. By the way, Ramp-Hold mode does not include the automatic heat work calculation that is built into Cone-Fire mode. ARCHIVED QUESTIONS & ANSWERS We have upgraded our search line at www.paragonweb.com . You can now quickly search for questions and answers by entering a keyword such as “drying,” “greenware,” or “sounds.” When you have a moment, please try the search line and let me know what you think of it. A GLASS FUSING POINTER Dr. Judy Fisher of Mitchellville, Maryland fuses glass in a small front-loading Paragon SC-2 jewelry kiln. She wrote, “I fire on two shelves. I know just how to position the glass pieces. I put the thicker ones toward the back and gradually reduce the thickness as I come toward the front of the shelves. The pieces are always nice and rounded.” RECENT Q&As Q. What is your opinion on drying almost dry clay pieces in the kiln on a 150-180 degree F. temperature hold? A. The ideal is to load only bone-dry ware into the kiln. However, if your schedule does not permit that, then candling the ware inside the kiln is fine. It is important to vent moisture from the kiln during candling. Continue the candling stage until signs of moisture leaving the kiln have disappeared. Moisture at higher temperatures in the kiln will cause excessive rusting, will slow down the firing, and will waste electricity. One method of detecting moisture is to hold a mirror near the upper peephole or vented lid. Moisture will fog the mirror. You can also feel the moisture with your hand. Q. When a digital kiln is firing too slowly due to either worn elements or low voltage, should the relays continue to make a clicking noise? A. No. The relays make a clicking noise when they cycle the elements on and off to control the firing rate. When the kiln is firing too slowly, the relays should give the elements 100 percent power by staying on continuously. Q. I need to fire a bisque mold for glass slumping. What program do you suggest? A. Here is a program for firing a glass sagging bisque mold to cone 06. Please make sure the clay is rated to that temperature. Also, do not attempt to fire to cone 6 (1828 degrees F.) unless your kiln is rated to that temperature. You will find the maximum temperature listed on your kiln’s electrical data plate. (The plate is attached to the side of the switch box or the back of the kiln on most models.) Cone 06 Segment 1: Rate 324 Temperature: 1022 Segment 2: Rate 153 Temperature: 1112 Segment 3: Rate 180 Temperature: 1720 Segment 4: Rate 108 Temperature: 1828 -------------- I hope you have a great weekend. Thank you, Arnold Howard Paragon Industries, L.P. – Better Designed Kilns 2011 South Town East Blvd. Mesquite, TX 75149-1122 Voice: 972-288-7557 & 800-876-4328 / Fax: 972-222-0646 ahoward@paragonweb.com / www.paragonweb.com PRIVACY NOTICE: Under no circumstance do we share or sell your email address. Copyright 2006, by Paragon Industries, L.P. |

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||