|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

KM24T Pro 3 Zone |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fast Firings Knife Making |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Paragon KM-24T Pro 3 Zone Knife Maker’s Heat Treating FurnaceTest exotic heat treating formulasAs the owner of a Paragon KM-24T Pro furnace, you can live the knife making adventure to the fullest with one of the most extraordinary furnaces we have ever developed. Knives have always accompanied explorers on great journeys. Yet knife making, itself, is an adventure all its own. It begins when the future owner shares the dream of a special knife with the maker. They talk excitedly over the first rough sketches. Then the maker retires to his shop and loses himself in the creation of the knife. Time disappears; the hours tick by as he grinds, heat treats, and polishes, sometimes well into the night. Try out the newest tool steels. Are they really as good as the tried and true D2 and A2? (Knives created from D2 or A2 will live on long after the owners have passed them on to loved ones.) The Paragon KM-24T Pro is rated to 2350° F, so you can heat treat as hot as you need to experiment with the new steels. Long lasting solid state relaysThe KM-24T Pro has three solid state relays, which last far longer than standard mechanical relays and offer better temperature control during holds. Solid state relays have no moving parts to wear out. They are silent. You will hear just the reassuring hum of the kiln’s heating elements. The relays are mounted to aluminum heat sinks for heat dissipation. Included with solid state relays is a safety relay for your peace of mind. 3 zone temperature control for superior heat distributionThe KM-24T Pro offers precise heat distribution throughout the length of the firing chamber. This is because it is divided into three zones. Each zone has its own thermocouple, or temperature sensor. The Sentinel controller electronically adjusts the temperature of each zone. See for yourself. Test for temperature uniformity by taking measurements along the length of a blade with a Rockwell Hardness Tester. Ceramic fiber firing chamber for fast heating and coolingThe KM-24T Pro is unusually fast, because it is made with space-age ceramic fiber. It can reach 500°F in minutes. Long lasting, “wavy” elements in the walls are surface-mounted to stay cool and therefore prolong element life. The guillotine door for years of comfortable heat treatingThe guillotine door is the ultimate choice for heat treating. The door lifts up and out of the way with one-handed operation. The hot side of the door remains away from you. The door lifts effortlessly with the assistance of a spring on each side. Because of the rigid case and heavy duty opening assembly, the door is sturdy enough for years of faithful service. Door safety switchThe door micro safety switch shuts off the power to the elements when the door is opened, yet the controller continues to give a temperature readout. The safety switch is standard on Paragon KM furnaces. No more waiting for commercial heat treatingA Paragon KM-series furnace sets the knife maker free. No more wrapping blades and shipping them to your heat treater. No more waiting until you have a dozen blades to get the best price on heat treating. No more turning away orders for last-minute gifts. While your furnace is hardening and tempering blades, you can busy yourself grinding more knives or fitting handles. After you’ve used your Paragon furnace awhile, you will wonder how you ever got along without it. When asked to make a knife on short notice—whether for a Marine Corps awards presentation, a celebration or retirement party, or an archaeologist on his way to Africa—you will be ready. When a custom knife is needed as a going away gift, and the recipient is leaving in three days, you will be ready. Your KM-series furnace might even pay for itself on rush orders you would otherwise have missed. Own a furnace and you alone decide when you will complete a knife. If you stay up one Friday grinding a knife, you can heat treat it that evening and deliver it Saturday morning. Just in time for a grateful wife to present to her husband on his birthday. Finishing a knife whenever you want will excite you. You will find yourself working into the night to complete a new design. When you send the blade out for heat treating, the excitement of making and designing it will have been forgotten. By the time the blade returns, you will hardly remember it. Solid furnace constructionThe furnace is insulated with 2 1/2” space-age ceramic fiber. The thermocouple wire is kept safely inside the case for protection from the harsh environment of the typical bladesmith shop.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

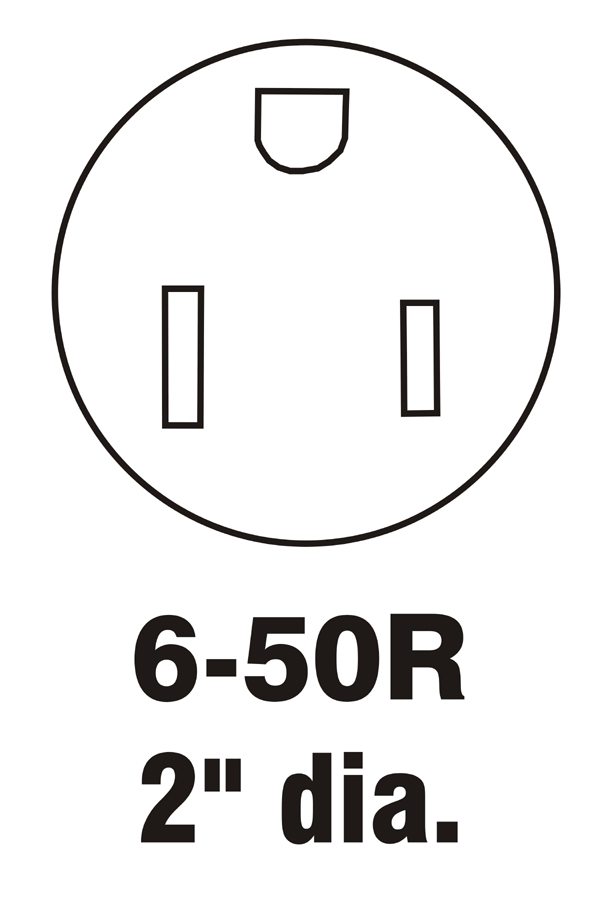

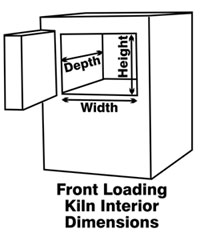

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Heat Treating Manual for KM & HT Series Sentinel Touch Screen Controller Instructions |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

KM24T Pro 3 Zone Kiln Model/SKU: S1710 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||