|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GL44ADTS |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Glass Fusing Glass Painting Glass Slumping |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

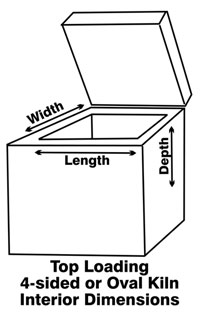

The Paragon GL-44ADTSD Glass KilnMade in AmericaThe deluxe GL-44ADTSD Professional Series glass kiln will help you to unlock your potential as a glass designer. The kiln quickly pays for itself by producing large glass panels, curved windows, lampshades, or production loads of glass pendants. Experiment with reactive glass colors, screen printing on glass, painting with frit and stringers, and glass weaving. The GL-44ADTSD is proudly made in America by skilled workers. It is not just assembled, but hand-crafted and designed for those whose livelihood depends on glass production. Heating elements in the lid and wallsThe 16” depth is ideal for glass sagging. The sidewall heating elements, mounted in all four sides, offer greater control of sagging and bending. The kiln uses advanced power ratio technology, pioneered by Paragon, to balance the heat between the top and side elements. Program the digital controller to balance the heat between the top and sides in increments of 10%. (i.e., 100% top - 0% sides, 50% top - 50% sides, 80% top – 20% sides, etc.) Set the heat balance for any combination desired between the top and sides so that the total heat output equals 100%. Imagine the precise control you will have in adjusting the kiln to slump glass or to improve heat distribution over large fused panels. The GL-44ADTSD has four peepholes along the front. When ordering the optional Orton KilnVent, be sure to specify whether you want peepholes. The GL-44ADTSD brick bottom holds two 20” square shelves. Cover shelves with fiber paper when large projects overlap shelves. Lid counter-balance, pinless lid elementsThe massive lid is easy to lift with Paragon's patented LiteLid spring counter-balance, which does away with cumbersome pulleys and cords and dramatically reduces lid weight. Unlike pulleys and weights, the LiteLid is self-contained on the kiln. There is no need to drill holes in the ceiling for pulleys. The LiteLid sharply reduces wear between the lid and top rim of firebrick. The truss and floating lid allow expansion of the lid. The GL-44AD comes with two LiteLid assemblies. The lid is insulated with 1” ceramic fiber and 3” ceramic fiberboard. Replaceable heating elements mount in lid fiberboard grooves. The groove eliminates element pins since the element coils are wider than the groove opening. Reinforced steel frame3” insulating firebrick lines the walls. A welded 2" tubular steel frame reinforces the kiln for long life. We are so confident in the GL-44ADTSD that we back it with a two year warranty. Rigorous constructionParagon’s GL-44ADTSD is made for years of rigorous firing. A double heat shield and air gap between the kiln and ventilated switch box help keep electrical components cool for long, trouble-free service. Costly heavy-gauge nickel-plated copper wiring is covered with high temperature glass-braided insulation. Save on shippingParagon is centrally located in Mesquite, Texas, along a major shipping route. This reduces shipping costs and delivery time to our customers. We pass the reduced shipping costs directly to you.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Videos

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Glass Kiln Instruction & Service Manual Sentry 2.0 12-Key Ramp-Hold Manual, 2010 Edition |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GL44ADTS Kiln Model/SKU: 44611P2GGP |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||