|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

F500 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Glass Annealing Lamp Working |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

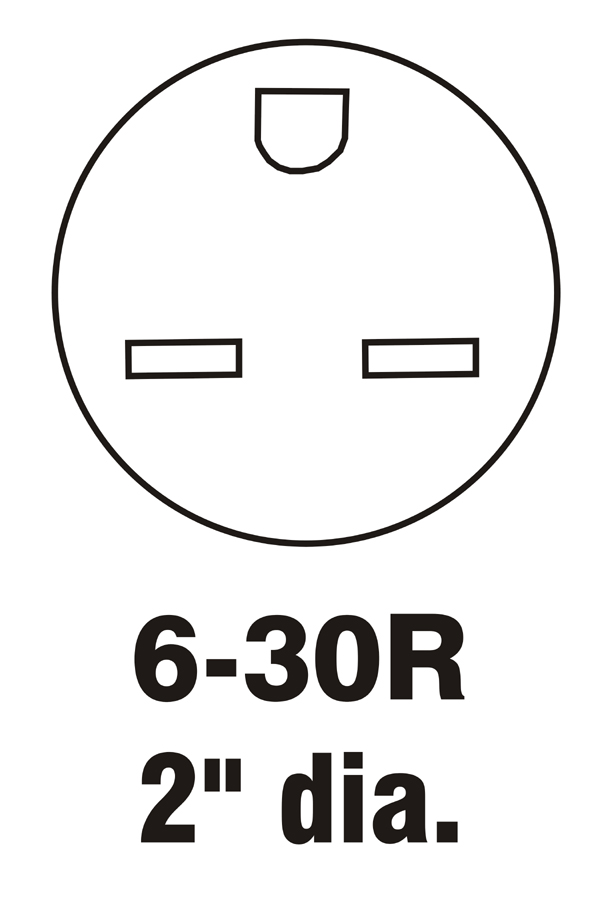

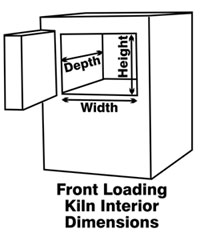

Paragon F-500 Lamp Working KilnWe are constantly improving the F-500. The kiln is designed for annealing large glass figurines, beads, and marbles and is made at the Paragon factory in Mesquite, Texas USA. Imagine the huge glass pieces you could make with a kiln this large. The massive F-500, with its towering door counter-weights and handsome black finish, is a workhorse that will raise your production. The F-500 simplifies annealing so you can immerse yourself in creating breathtaking ware. Raise the counter-weight vertical-drop door to insert a punty rod and glass. Lower the door. The punty rod extends outside the firing chamber through a smaller punty rod door. The main door is balanced so it stays open where you stop it. Maintain the annealing temperature indefinitely with the Sentry Xpress 3-key controller. Two 4” x 10 1/2” punty rod doors retain the heatThe main door includes two 4” x 10 1/2” punty rod doors. Two flexible gaskets under each door help to retain the heat. The punty rods can extend outside the kiln through the gap under the doors. This allows the doors to remain fully closed. The ceramic fiber punty rod doors are a full two inches thick to help retain heat. Rare-earth magnets hold the doors in the open and closed positions. Adjustable rod restYou can adjust the rod rest, which is positioned in front of the punty rod doors, with wing bolts. Adjust it horizontally and vertically without tools. Or remove the rod rest altogether when you don’t need it. You can order the optional stand for the F-500, with or without casters. Durable 3” thick insulating firebricks; side elementsThe insulating firebricks, wrapped in heavy-gauge steel, soak up heat for slow, efficient cooling. The firebricks are 3” thick, 20% thicker than the standard 2 1/2” bricks, throughout the top, walls, bottom, and door. The heating elements are protected in dropped, recessed wall grooves for trouble-free firing. Wires are fastened to the elements with heat-dissipating connectors refined and proven over many years in Paragon kilns. Elements are coiled from the finest high-temperature wire available. The F-500 has no roof elements. Heavy duty componentsCostly heavy-gauge nickel-plated copper wiring is covered with high temperature glass-braided insulation. Features of the F-500

We are open from 7 a.m. to 5:30 p.m. Central Standard Time, Monday through Thursday. Our expanded hours allow us to serve customers in differing time zones. Call us—we look forward to hearing from you.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Videos

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Sentry Xpress 4.0 3-Key Controller: Single Segment and Ramp-Hold Sentry Xpress Controller Quick Start Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

F500 Kiln Model/SKU: 9G611J3EGP |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||