|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BlueBird |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Glass Bead Annealing |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

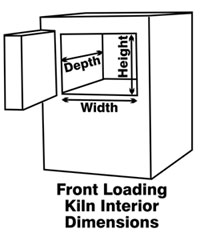

The BlueBird safely anneals glass beads to prevent breakage during cooling. The kiln, made in America to exacting standards, opens doorways of opportunity in beadmaking. Enjoy a full 20” of width with the 2” x 10” / 50mm x 254mm double doors. This kiln is ideal for busy seminar teachers. It is like having two kilns in one. Improved ceramic fiber firing chamberThe BlueBird features new sinusoidal “wavy” elements, which are embedded close to the inner surface of the high-tech, vacuum-formed ceramic fiber top. This is an improvement over our earlier embedded coiled elements, because the “wavy” elements are mounted closer to the surface. This enables the elements to radiate heat faster for longer element life. The ceramic fiber top reduces dust inside the kiln. The BlueBird features space-age ceramic fiber walls and bottom for fast, efficiently heating. Mandrel holders, glass rod warmerInsert bead mandrels into the kiln. The mandrels rest outside the kiln on a 3”-deep slotted stainless steel mandrel holder, cradled at two points. We have added exciting new performance-enhancing features to the BlueBird, such as the glass rod warmer on top of the kiln. Pre-heating glass rods saves production time. Door latches and rare-earth magnetsSide latches hold the doors closed while the kiln is heating to annealing temperature. Phenolic knobs stay cool to the touch. Rare-earth magnets hold the doors open when needed. A safety switch on the front panel turns off power to the controller when the kiln is not in use. Use the switch to reboot the controller when needed. Sloped panel for easy operationTo save table space, the Sentry Xpress digital controller is mounted under the kiln in an ergonomic, sloped panel for easy operation. The built-in base stays cool even during extended hold times. It is slotted to dissipate heat and comes with mar-proof rubber feet. The steel base supports the kiln in two layers. The upper steel base supports and strengthens the ceramic fiber floor; the lower steel base covers the entire kiln bottom where it rests on your worktable. Electrical components are mounted to the lower base, away from the heat of the firing chamber. Economical to fireThe BlueBird plugs into a standard household outlet. It draws only 1,500 watts. The kiln ships by convenient UPS/FedEx. Specially designed cartons and vacuum-formed padding assure that the kiln will arrive safely. Digital controllerThe BlueBird’s user-friendly 3-key Sentry Xpress digital controller automatically maintains the annealing temperature that you select. The controller is packed with features but is user friendly.

"Daniel and I are a husband and wife team and love the fact that with the BlueBird we have plenty of space for our beads when working together in the studio. Wonderful kiln!" -- Jenelle Aubade of SFD Glass Studio in Fayetteville, North Carolina. You can download a free copy of a lampworking bead tutorial. Click here.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Videos

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Accessories |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Usages

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Additional Information

Sentry Xpress 5.0 3-Key Single-Speed / Ramp-Hold Instructions, March 2019 Edition Sentry Xpress Controller Quick Start Guide |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BlueBird Kiln Model/SKU: S1716 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

“Custom and standard Kilns and Industrial Furnaces for ceramics, pottery, heat treating, enameling, |

||||